STEP #1 - Preliminary Inspection

Our watchmaker conducts a detailed inspection, carefully analyzing all components and functions of the watch. Each timepiece is evaluated against factory specifications and its unique aesthetic features to ensure a thorough understanding of its condition and needs.

STEP #2 - Diagnosis

After a thorough inspection, our watchmaker evaluates the condition of your timepiece and identifies the necessary repairs. We then schedule a personalized phone call to discuss our findings, explain what your watch needs, and answer any questions or concerns you may have. This personalized approach ensures you fully understand the work required and feel confident before moving forward with the repair.

STEP #3 - Case Disassembly & Pre-Cleaning

Once the estimate is approved, the watch is carefully disassembled. The bracelet and movement are removed from the case, and all components—such as the bezel, crystal, gaskets, and pushers—are meticulously dismantled. The movement then undergoes a pre-wash to remove initial debris and prepare it for detailed servicing.

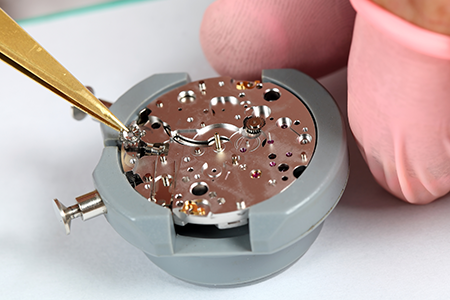

STEP #4 - Complete Movement Disassembly

The movement is fully disassembled, with each component carefully examined under magnification. Our watchmaker assesses the condition of every part to determine whether it requires repair, replacement, or adjustment based on its level of wear. This meticulous process ensures the movement is restored to optimal performance.

STEP #5 - Washing

All movement components are carefully placed into a series of ultrasonic baths using specialized cleaning solutions. This process thoroughly removes dirt, grease, and debris, ensuring each part is spotless and ready for reassembly.

STEP #6 - Case & Bracelet Refinishing (Optional)

When requested, the watch case and bracelet are meticulously refinished to restore their original luster while preserving the authentic shape and cosmetic details of the individual model. This process ensures your timepiece looks as close to its original condition as possible.

STEP #7 - Movement Assembly & Lubrication

The movement is meticulously reassembled, with each component precisely placed and aligned. Specialized oils and greases are carefully applied based on the movement's mechanical complexity to ensure smooth operation. Adjustments are made as needed to meet model-specific specifications, restoring the movement to peak performance.

STEP #8 - Case Reasembly

The watch case is meticulously reassembled, and the movement is carefully inserted and secured. All gaskets and seals are replaced as needed to ensure proper protection, and the case is tightly sealed. The watch undergoes pressure testing to verify its water resistance, and the bracelet is reinstalled to complete the process.

STEP #9 - Pressure Test/Water Resistance Test

Once the case is fully reassembled, the watch undergoes a water resistance test using specialized equipment. Compressed air pressurizes a chamber where the watch is monitored with a sensitive probe to detect any leaks. If the watch does not pass this test, additional equipment is used to identify and resolve the issue, ensuring the watch is properly sealed and protected.

STEP #10 - Timing Analysis & Quality Control

In the final stage, the watch undergoes extensive timing analysis over several days, tested in multiple positions to ensure its accuracy and functionality. A thorough inspection is also performed to verify the cosmetic appearance meets our high standards. This final step guarantees your timepiece is returned in optimal condition.